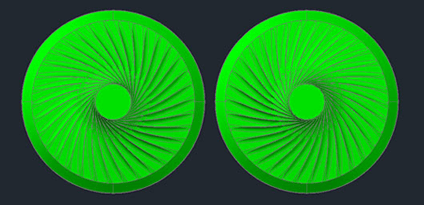

Swirling Intake Valves

Revolutionary Intake valves Twist the fuel and air mixture to get a better blend

Introducing LPC Swirling Intake Valves

When was the last time you've been in traffic and the emissions of the cars around you did bother you, or even made you feel sick? The solution are the LPC Swirling Intake Valves.

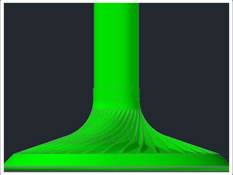

Engineered by LPC Electronics to fight the heavy toll cars, motorbikes and electric-powered generators leave on the air, these valves are designed to twist the fuel-air mixture getting better mixture. Using the Coanda effect for fluids, most of the mixture will be directed under the intake valve, towards the piston and not towards the cylinder walls The end result is a more efficient, environment friendly product for the consumer.

How the Valves Work

The valves are designed to twist the fuel and air mixture to get a better blend. Using the Coanda effect for fluids, most of the mixture will be directed under the intake valve, towards the piston and not towards the cylinder walls. The end result is a more efficient, environment friendly product for the consumer.

Why Our Valves are Better

Better

Mixture

LPC Swirling Intake valves will twist the fuel-air mixture getting a better blend.

Better

Emissions

Even a low RPMs, the valves increase the efficiency of the combustion meaning less emissions.

Better

Efficiency

Because LPC Electronics has increased combustion efficiency, the result is more torque and power.

Combustion Engine Facts

Cars, scooters, motorbikes, electric power generators and power tools are very useful in our modern lives… but all come with a price: emissions, air pollution, global warming.

- When combustion engines operates at low RPMs (city driving, stop and go) or operates while the transmission is switching between gears; the fuel-air mixture is far from uniform or homogeneous, and the combustion is far from efficient and clean; slow and incomplete combustion occurs… generating high emissions and low torque.

- When operating the combustion engines at HWY speeds, and the engine's RPM is higher than 2,000 RPMs, the fuel-air mixture is more homogeneous and that leads to better mileage and low emissions.

- Inside the combustion chamber valves and the pistons are hotter; the heat can only dissipate through the valve sealing area or piston rings.

- Cylinder walls are cooler that valves and pistons; they are cooled more efficiently by the coolant system that flows in the engine block around the cylinder walls.

- Ideally, the fuel-air mixture should go around the intake valves and hit the piston, cooling it down and use that heat to better prepare the ignition.

- Practically a lot of the fuel-air mixture goes on the cylinder walls, washing the oil and condensing due to the colder walls.